DEVICES FOR DEPOSITION OF WEARPROOF COATINGS BASED ON CARBON, METALS AND THEIR NITRIDES AND CARBIDES

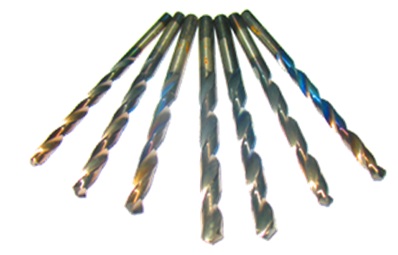

Vacuum assembly is used to produce solid «diamond-like» coatings, as well as TiN, TiAlN, TiCN, TiAlCN, CrN, CrTiN,  ZrN, AlZrN, AlTiZrN, and extra-hard nanocomposite coatings, such as TiN-Si3N4-TiSi2.

ZrN, AlZrN, AlTiZrN, and extra-hard nanocomposite coatings, such as TiN-Si3N4-TiSi2.

Parts identification:

- Two sources of metallic plasma with electromagnetic separation of plasma stream;

- An impulse generator of carbon plasma;

- YAG:Nd3+ laser for evaporation of dielectrics;

- Management of vacuum assembly and technological process on the basis of the controller Siemens Simatic S-1200.

Advantages:

Maximum set of equipment for reasonable price. Individual approach for solving problems of each project. Up-to-date setup, automated control system for equipment and technological process. We use the latest developments and components of world leaders in the field of vacuum deposition of thin coatings in our products.

We offer the following ways of cooperation:

- Development, production, supply, installation supervision, adjustment, equipment settings, warranty and post-warranty service;

- Engineering services, such as: research, design, technological works on vacuum technologies and equipment in accordance with the consumer’s purposes.

ALEXANDER ROGACHEV,

DIRECTOR OF PHYSICO-CHEMICAL RESEARCH AND DEVELOPMENT INSTITUTE,

CORRESPONDING MEMBER OF THE NATIONAL ACADEMY OF SCIENCES OF THE REPUBLIC OF BELARUS,

DOCTOR OF CHEMICAL SCIENCES, PROFESSOR,

tel. (+375 232) 50 38 03, fax (+375 232) 51 00 77,

e-mail: rogachevav@mail.ru,

http://nis.gsu.by