MODIFICATION OF RUBLER-TECHNICAL ARTICLES FOR APPROPRIATION OF ANTIFRICTION PROPERTIES

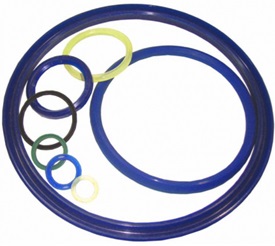

Can be used  in sealing units of hydro-pneumatic-fuel systems of automotive engineering, machine-tool construction, automation devices and fine mechanics.

in sealing units of hydro-pneumatic-fuel systems of automotive engineering, machine-tool construction, automation devices and fine mechanics.

Technology characteristics

Processing of the articles with application of the offered technology is carried out by applying of a composite polymer layer (0.1 – 2.0 μm) on the surface of rubber-technical articles using methods of plasmochemistry. The coatings are applied to butadiene-nitrile, siloxane and other types of rubbers in order to increase the service life of rubber-technical products and their resistance to negative effects of aggressive media.

Advantages and technical caharaqcteristics:

Advantages and technical caharaqcteristics:

- Reduction of coefficient of friction to 1.5-4 times.

- Reduction of wear and «sticking» to the mating surface.

- Reduced swelling of modified rubbers when working in a fuel and oil environment – 2-6 times.

- Extended service life of modified rubbers up to 6 times.

- Modification technology for rubber-technical articles is ecologically pure.

The technology is developed by the educational institution Francisk Skorina Gomel State University in cooperation with the educational institution Belarusian State Transport University.

ALEXANDER ROGACHEV,

DIRECTOR OF PHYSICO-CHEMICAL RESEARCH AND DEVELOPMENT INSTITUTE,

CORRESPONDING MEMBER OF THE NATIONAL ACADEMY OF SCIENCES OF THE REPUBLIC OF BELARUS,

DOCTOR OF CHEMICAL SCIENCES, PROFESSOR,

tel. (+375 232) 50 38 03, fax (+375 232) 51 00 77,

e-mail: rogachevav@mail.ru,

http://nis.gsu.by