TECHNOLOGY OF FORMATION OF SUPERHYDROPHOBIC COATINGS

Applied  in textile industry (processing of fabrics and footwear), in the manufacturing of glasses, medicine (treatment of needles for blood sampling), treatment of cellulose-containing materials.

in textile industry (processing of fabrics and footwear), in the manufacturing of glasses, medicine (treatment of needles for blood sampling), treatment of cellulose-containing materials.

Technology characteristics

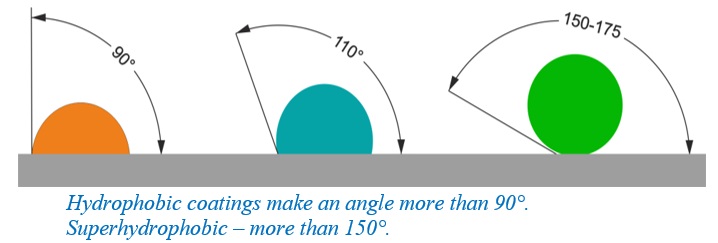

Superhydrophobic coatings have the following characteristics: a drop of water forms on the coating an angle of wetting of more than 150°; a rolling angle, i.e. the angle of inclination of the surface to the horizon, at which a drop with a diameter of 2-3 mm begins to slide, does not exceed a dozen degrees.

Deposition of these coatings to fabrics or footwear gives the effect of self-cleaning of the surface when contacting with water droplets, and formation on the surface of the glass allows to solve the problem of cleaning glass and facades from contamination. Application of superhydrophobic coatings to the paper surface provides a water repellent effect and minimizes the destructive effects of humid environment. The developed technology includes formation by the method of electron beam dispersion on the surface of various materials of hydrophobic coatings based on polytetrafluoroethylene, paraffin or silicone resin. Such coatings provide a wetting angle of 120-160 °.

Advantages of the coatings developed

Advantages of the coatings developed

- Hydrophobic effect.

- Can be applied to any material.

- Impart water-repellent antifungal properties to cellulose-containing materials.

- Provide the surface self-cleaning effect.

- Environmentally friendly technology.

- Thickness of coatings –5-1.0 μm.

- Angle of wetting is from 120 – 160°.

ALEXANDER ROGACHEV,

DIRECTOR OF PHYSICO-CHEMICAL RESEARCH AND DEVELOPMENT INSTITUTE,

CORRESPONDING MEMBER OF THE NATIONAL ACADEMY OF SCIENCES OF THE REPUBLIC OF BELARUS,

DOCTOR OF CHEMICAL SCIENCES, PROFESSOR,

tel. (+375 232) 50 38 03, fax (+375 232) 51 00 77,

e-mail: rogachevav@mail.ru,

http://nis.gsu.by