POLISHING SUSPENSIONS FOR THE FIRST AND SECOND STAGES

OF CHEMICAL-MECHANICAL POLISHING OF SINGLE-CRYSTALLINE SILICA PLASTICS

They are ultradispersed stabilized colloidal systems based on pyrogenic silicon dioxide.

Description

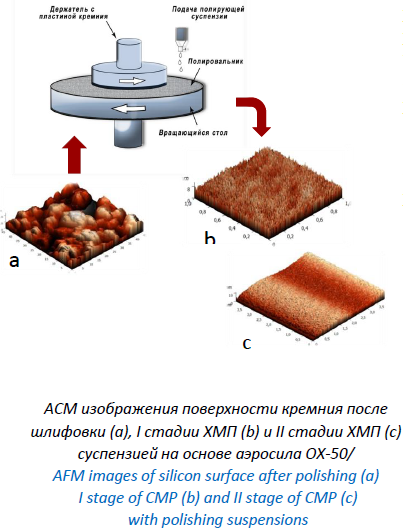

Polishing suspensions are proposed for the first and second stages of chemical-mechanical polishing of silicon wafers of various orientations, as well as other applications.

Technical and economical advantages of production

- Polishing suspensions provide: high surface cleanliness after polishing, a low amount of static electricity generated on the polisher, high productivity, ease of use, high stability and minimal contamination with metal ions

- The efficiency of chemical-mechanical polishing of monocrystalline silicon wafers is to obtain a mirror, smooth, flat surface with nanometer (subnanometric) roughness at a sufficiently high material removal rate

- Suspensions based on pyrogenic silicon dioxide contain particles of the minimal possible size to ensure uniformity of the geometric and structural properties of the polished surfaces;

Suspensions are homo-geneous in terms of phase and element composition, highly stable, easy to prepare and use, cheap and environmentally safe.

VLADIMIR GAISHUN

HEAD OF ADVANCED MATERIALS RESEARCH LABORATORY

CANDIDAT OF PHYSICS AND MATHEMATICS, DOCENT

TEL. +(375 232) 50-38-22, FAX +(375 232) 50-38-13,

E-MAIL: VGAISHUN@GSU.BY, http://pnil.gsu.by/

QR code for this page: